Comfortable Chair Woodworking Plans for Crafting Stylish Seating

The creation of a comfortable and stylish chair represents a pinnacle achievement in woodworking. This undertaking, while demanding patience and precision, offers unparalleled satisfaction in the final product: a handcrafted piece reflecting both skill and aesthetic vision. This comprehensive guide delves into the design considerations, material selection, and meticulous construction techniques required for crafting a comfortable wooden chair, ensuring a rewarding experience for the woodworking enthusiast.

I. Design Considerations: Blueprint for Comfort and Style

Before embarking on the construction process, a thorough understanding of design principles is crucial. The chair's comfort and aesthetic appeal are directly linked to careful planning and thoughtful consideration of several key aspects.

A. Chair Style and Ergonomics

Selecting a suitable chair style forms the foundation of the project. Consider the intended use of the chair. Will it serve as a dining chair, an armchair for relaxation, or a statement piece in a living room? Popular styles include Shaker chairs, Windsor chairs, Adirondack chairs, and modern minimalist designs. Each style presents unique ergonomic challenges and construction techniques. Researching different styles will illuminate the various approaches to comfort and structural integrity.

Ergonomics plays a pivotal role in chair design. A comfortable chair should offer adequate lumbar support, proper seat depth and height, and comfortable armrests (if included). The angle of the backrest should promote good posture, preventing slouching and strain. Detailed sketches and potentially 3D modeling can greatly aid in refining the ergonomic design, ensuring a harmonious blend of form and function.

B. Material Selection: The Foundation of Durability and Aesthetics

The choice of wood significantly impacts the chair's durability, aesthetic appeal, and workability. Hardwoods such as oak, maple, cherry, and walnut offer superior strength and longevity but can be more challenging to work with. Softwoods like pine and fir are easier to shape and carve but may require more reinforcement for structural integrity. The specific characteristics of each wood species—grain pattern, color, and density—should align with the chosen design and personal preferences.

Consider the following factors when selecting wood:

- Strength and Durability: Select wood species known for their strength and resistance to wear and tear.

- Workability: Choose a wood that is easily workable with the tools and skills at your disposal.

- Aesthetic Appeal: Select a wood species that complements the overall design and desired aesthetic.

- Cost: Consider the budgetary constraints when selecting the wood.

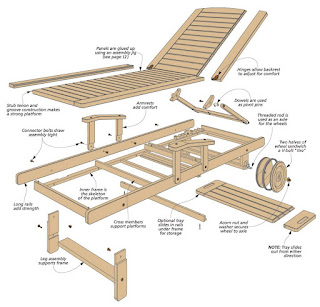

C. Joint Selection: Ensuring Structural Integrity

The success of a chair hinges upon the strength and precision of its joints. Various joint types offer varying degrees of strength and aesthetic appeal. Common joint types include:

- Mortise and Tenon: A classic and robust joint, ideal for strong chair legs and back supports.

- Dovetail Joints: Exceptional strength and an attractive visual appeal, often used in seat rails and backrests.

- Dowel Joints: Simpler to construct but may require additional reinforcement for high-stress areas.

- Through Tenons: Offer robust connections but require precise mortise cutting.

Selecting the appropriate joint type for each component is critical. A thorough understanding of joint construction is paramount for creating a structurally sound and aesthetically pleasing chair.

II. Construction Techniques: Precision and Patience

The construction phase requires meticulous attention to detail and precise execution. Each step must be undertaken with care, ensuring accuracy and consistency.

A. Cutting and Shaping: Achieving Dimensional Accuracy

Accurate cutting and shaping of the wood components are essential. Utilize precise measuring tools such as rulers, squares, and marking gauges to ensure dimensional accuracy. Employing a table saw, miter saw, and hand saws will aid in achieving clean cuts. Shaping the curved components may require the use of a bandsaw, spokeshave, or carving tools, depending on the chair's design.

B. Joint Construction: The Heart of the Chair's Strength

Constructing the joints with precision is critical for the chair's stability and longevity. Utilize appropriate joinery techniques, ensuring accurate fitting and tight joints. Employing clamps and jigs will aid in maintaining alignment during glue-up. Properly fitting joints are the key to a strong and durable chair.

C. Assembly and Finishing: Bringing the Design to Life

Once all components are cut and the joints are constructed, the assembly process begins. Work methodically, ensuring each piece is properly aligned and securely fastened. Use appropriate clamps and screws to reinforce the joints during assembly. The final finishing process involves sanding, staining, or painting, protecting the wood and enhancing its aesthetic appeal. Apply multiple coats of finish, allowing each coat to dry completely before applying the next.

III. Advanced Techniques for Enhanced Comfort

Beyond basic construction, incorporating advanced techniques can elevate the chair's comfort and aesthetic value.

A. Upholstery and Cushioning: Adding Layers of Comfort

For added comfort, consider upholstering the chair seat and backrest. Select high-density foam padding and durable upholstery fabric. Properly attaching the upholstery requires attention to detail, ensuring a snug and comfortable fit. This adds a significant dimension to the overall comfort and visual appeal of the finished piece.

B. Curvature and Shaping: Optimizing Ergonomic Design

Careful shaping of the seat and backrest can significantly enhance the chair's ergonomics. Creating gentle curves that conform to the body's natural contours promotes comfort and proper posture. Steam bending techniques can be employed to create more dramatic curves in the chair's components.

IV. Safety Precautions: Protecting Yourself and Your Workspace

Woodworking involves inherent risks, necessitating adherence to safety protocols. Always wear appropriate safety glasses, ear protection, and dust masks. Use caution when operating power tools, ensuring proper setup and maintenance. Maintain a clean and organized workspace to prevent accidents.

Crafting a comfortable wooden chair is a rewarding journey. By meticulously following these plans, employing precision techniques, and prioritizing safety, the woodworking enthusiast can create a stylish and functional piece that provides years of enjoyment. Remember that practice and patience are key to mastering woodworking skills, leading to the creation of beautiful and enduring pieces.

No comments:

Post a Comment